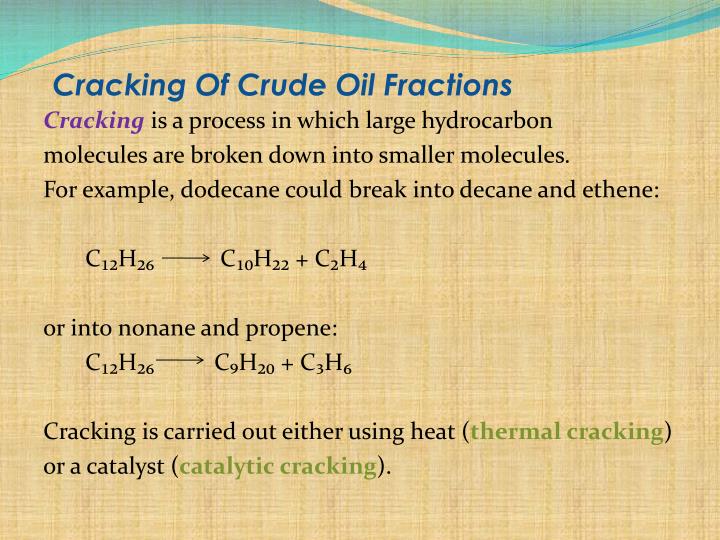

The major reasons for this include sustainability of fuels derived from renewable sources that support ecosystem and human heath as well as long-term goals on tolerable emissions. Despite this, however, the popularity and the public acceptance of biofuels are on the increase. This constituent lowers the quality of the biofuel and thereby restricts its application. However, the major drawback of biofuel from pyrolysis is the oxygen contents, which is responsible for its low heating value, instability, and high acidity (Pütün et al. The liquid biofuel could be biocrude, synthetic oils, and biodiesels (Demirbas 2007a, 2008a,b, Gerçel and Gerçel 2007, Gonzalez et al. The product of this process include gaseous, liquid, and solid biofuels. Fast pyrolysis is the most commonly used method for biofuel production from biomass because it is economically viable and thermally efficient (Apaydin-Varol et al. Techniques currently explored in producing these biofuels include thermal cracking (pyrolysis), coblending with VGO, and microemulsion of biomass (Gómez et al. Biomass from fast pyrolysis possess high potentials for producing biofuels and other specialty chemicals for replacing fossil fuel-derived products (Demirbas 2009, Botas et al. Thus, the public outcry for urgent solutions explains the need to seek alternative and sustainable sources of energy. Also, because of the excessive use of these conventional fuels, crude oil exploration is said to have reached its peak (Mohammad et al. Furthermore, these fuels are nonrenewable, often scarce with unpredictable prices. The use of fossil fuels in several sectors, such as heat and power generation, and transportation create environmental hazards from emission of greenhouse gases (Graça et al. However, despite these many advances, the need for further investigations to achieve excellent catalytic activity for industrial scale-up persists. Further, the approaches improve catalytic activity, selectivity, and TOS stability because of the lower formation of coke precursors such as polynuclear aromatics. Interestingly, these deactivation-suppression techniques enhance catalytic properties mostly by reducing the signal strength of strong acid sites and increasing hydrothermal stability. The review also analyzes deactivation-suppression techniques such as nanocrystal zeolite cracking, hydrogen spilt-over (HSO) species, and composite catalysts (hybrid, hierarchical mesoporous zeolite, modified zeolites, and catalytic cracking deposition of silane). To understand the concept of catalyst deactivation and to offer solutions, the review scrutinized the deactivation mechanism diligently.

Thus, this article reviews recent advances aimed at alleviating these setbacks to make the process viable for industrial scale-up. These cumulate into the loss of catalytic activity with time on stream (TOS), which causes low degree of deoxygenation. This is because of leaching of active species, coking, and concomitant catalyst deactivation.

#CRACKING OF DODECANE TO MAKE ETHENE HYBRIDIZATION UPGRADE#

The economic viability of the thermocatalytic upgrade of biomass-derived oxygenates is facing the challenge of low-quality products.

0 kommentar(er)

0 kommentar(er)